Blog

RSS FeedOur goal at Rental Tools Online is to provide the top products on the market at the lowest possible prices, while providing the best possible customer experience. Our staff is very knowledgeable on all our advertised brands and are here to help you choose the best product for your specific application.

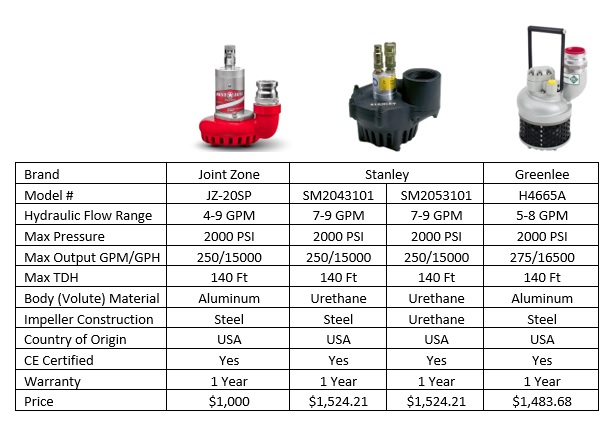

There is no recoil starting, priming or suction hoses required to run these units and they can run dry without damage. The performance of all three brands is very similar, with the Greenlee H4665A having a slightly higher maximum output compared to the Joint Zone JZ-20SP and the Stanley SM20’s. The major differences between the highlighted models are the materials used in the body and impeller, and the prices. The prices speak for themselves so we will focus on the materials.

MATERIALS

Body (Volute):

- Urethane bowls are very lightweight and can do a good job with clean, clear water. It is not recommended for water that has a lot of abrasives in it as these will eventually deteriorate the tolerances between the impeller and volute causing a reduction in performance. They are not as long lasting if used for pumps with potential solids, like trash or sewer pumps.

- Aluminum is a great alternative to urethane. Although it is not as light as the urethane plastic, it is significantly lighter than iron and is much more abrasion resistant than urethane. Aluminum is generally better for use in salt water and corrosive liquids as it is inherently more corrosion

resistant than iron. It is not as impact resistant as iron however and may crack with a significant impact to the housing.

Impeller:

- Urethane impellers are very good for the same types of conditions as urethane bowls: cool, clean, clear water. The water should be less than 100 degrees or so to avoid distorting the shape of the impeller. It is not recommended for pumping solids, as these can cause the plastic to crack or break.

- Stainless Steel is the ideal choice for salt water or other corrosive liquids. It is very stable under different temperatures and pressures and will usually be unaffected by pumping smaller solids.